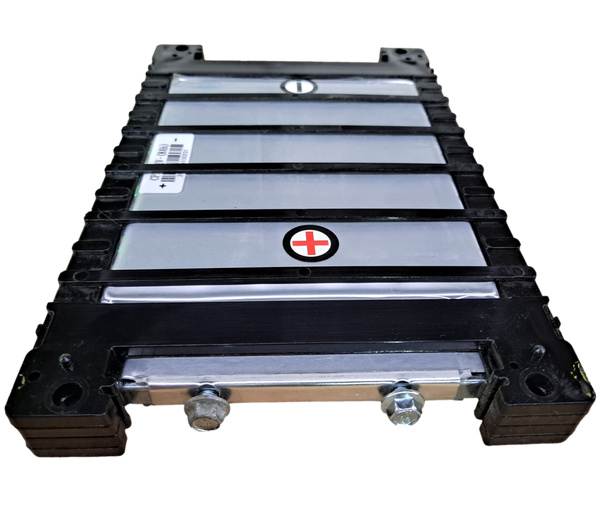

SPIM08HP 3.7V 16AH - Excellent Lithium Ion Power Cells

CELL HOLDERS, THREADED INSERTS, AND BOLTS INCLUDED.

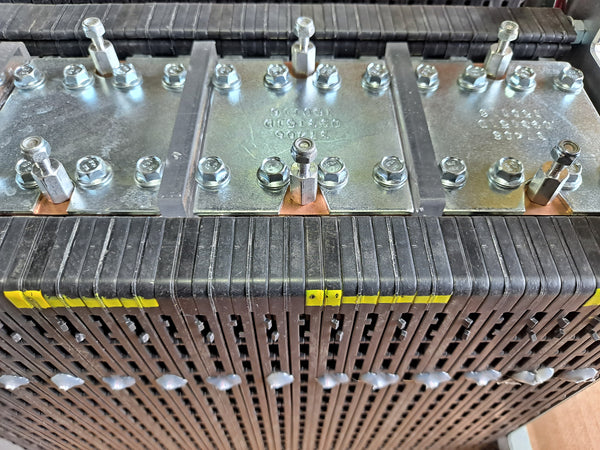

YOU CAN BUILD YOUR PACKS WITH JUST A WRENCH. WE HAVE THE BUSBARS FOR SALE AS WELL OR MAKE YOUR OWN. THESE MODULES ARE 3.7V 16AH AND THEY CONSIST OF 2X SPIM08HP 8AH CELLS IN PARALLEL. THERE IS A THREADED INSERT WITH THE BOLTS ALREADY ON. IT DOESN'T GET ANY EASIER. THESE CELLS ARE RATED FOR 200A CONTINUOUS EACH WITH PROPER COMPRESSION AND COOLING. YOU CAN SIMPLY USE THREADED RODS IN THE CORNERS OF THE CELL HOLDERS TO COMPRESS.

PERFECT FOR POWERWALLS, GOLF CARTS, FORKLIFTS, RV, EBIKES, ETC.

THESE CELLS WERE REMOVED FROM PACKS THAT WERE USED AS BACKUP ONLY. WE TESTED TENS OF THOUSANDS OF THESE AND SOLD TRUCKLOADS ALREADY. ON AVERAGE YOU CAN EXPECT 95% OF ORIGINAL CAPACITY. EVERY MODULE IS CHECKED FOR VOLTAGE. CHARGE EACH MODULE UP TO 4.2V THEN BUILD YOUR PACK. ADDING A BMS DOES NOT GET ANY EASIER. YOU CAN SIMPLY ADD SOME RING TERMINALS TO YOUR BMS CONNECTIONS AND BOLT THEM DOWN.

THESE LITHIUM ION CELLS ARE 2000 CYCLE RATED.

Material Li-ion

module specs

Typical capacity 16AH

Nominal Voltage 3.7V

Weight : 1 LB 12 OUNCES

Dimensions of cell body: 9x138X190mm

Dimensions of cell with tabs 9x138X210mm

Dimensions of cell module: 8 5/8" x 5 5/8" by 3/4"

Internal Resistance ≤0.8mΩ

Max Charge Rate 240A

Recommend MAX Continuous Discharge Rate 400A

Pulse Discharge Rate(3 seconds) 800A

Fully Charged voltage 4.2V

Discharge cut off voltage 2.5V

Working Charge Temp 0~50°C

Working Discharge Temp –20°C~50°C

Storage Temperature –20°C~50°C

Cell Specifications

Nominal Voltage:

Chemistry:

Full Charge Voltage:

Full Discharge Voltage:

Capacity:

Max Continuous Charge: A

Max Continuous Discharge: A

Calculate Your Battery Pack

This calculation also takes into consideration the maximum continuous amp ratings of the 2x 8ah cells in parallel to make the 3.7v 16ah cell modules. It is not recommended to run these cells at that high rate without cooling and proper compression.

The 3rd photo shows how these can be built. We sell these busbars as well or you can make your own. Note the busbars must be at least 3/16" thick for the bolts to tighten all the way. If you use thinner busbars you will need to trim the bolts shorter. All the busbars we sell for these are at least 3/16" thick.